The Cold Hard Facts About Steel Types and Grades

Over the past two decades, steel have evolved into a stronger, lighter metal that offers a vast array of types and grades. Here’s the inside scoop on the various kinds of steel.

Steel is gaining popularity in residential construction. Since skyscrapers were first constructed, steel has been a go-to for a commercial building, but a recent rise in residential popularity has placed steel back at the forefront of the construction world.

Thinking about building with steel? Not really sure what the difference is between steel types and grades?

This guide will give you a quick rundown of the 4 main types of steel and how grading gets assigned to each type of steel.

You’ll be able to talk steel with your builder in no time.

Steel Types

Steel Types

The term steel refers to an alloy made from iron and carbon. There are four main groups of steel, or steel types, that you can choose from.

Physical properties and chemical structures determine the steel classification or type.

1. Stainless Steel

The most well-known type of steel is probably stainless steel.

Stainless steel is a common residential metal. Home appliances, cooking utensils, backyard grills, and other products are stainless steel construction.

It is corrosion-resistant and typically shiny in appearance. It is very strong, and great for high-temperature applications.

Stainless steel has a low carbon content. It contains 10-30% chromium, and can at times contain other metals such as molybdenum and nickel. Stainless steel with a higher chromium content will have a greater resistance to corrosion.

There are three main types of stainless steel. Stainless steel can be further broken down into these three groups based on the crystalline structure of the metal alloys.

- Austenitic: Austenitic steels make up the majority of stainless steel. They are typically used for food processing equipment and kitchen appliances.

- Ferritic: Ferritic steels are magnetic and contain aluminum or titanium. They are great for welding.

- Martensitic: Martensitic steels are magnetic and heat-treatable steels. They are generally used to make knives and other cutting tools. They can be oftentimes found in dental and surgical equipment.

2. Alloy Steel

2. Alloy Steel

Alloy steel is less expensive than other types of steel. It can be commonly found in automotive parts, motors, piping, and other mechanical applications.

Alloy steel is named such because it has multiple alloying elements added to it. Some added alloying metals include silicon, titanium, chromium, and nickel. The strength and properties of alloy steel is dependent on the concentration of each added element.

Adding alloying elements enhances certain features of the steel. This makes alloy steel popular in many industries because it is versatile.

3. Carbon Steel

3. Carbon Steel

Carbon steel appears matte and dull in comparison to stainless steel. It is also vulnerable to corrosion.

The category of carbon steel is then broken down into three subcategories:

- Low Carbon: Low carbon steel is the most common. It’s used for sheet metal, structural beams and strapping. It typically contains less than 0.3% carbon.

- Medium Carbon: Medium carbon steel contains up to 0.6% carbon and manganese. It is stronger and harder than low carbon steel but it is more difficult to work with. It’s used for galvanized steel strapping.

- High Carbon: High carbon steel contains up to 1.5% carbon. It is the strongest of the carbon steels. It can become brittle and is difficult to work with.

4. Tool Steel

4. Tool Steel

Tool steel is used to make metal tools, as the name implies. The most common found tool steel is a hammer, but tool steel is also used in all stamping, mold-making, and cutting tools.

Tool steel is known for its hardness. It’s used to make metal tools that cut or shape other metals.

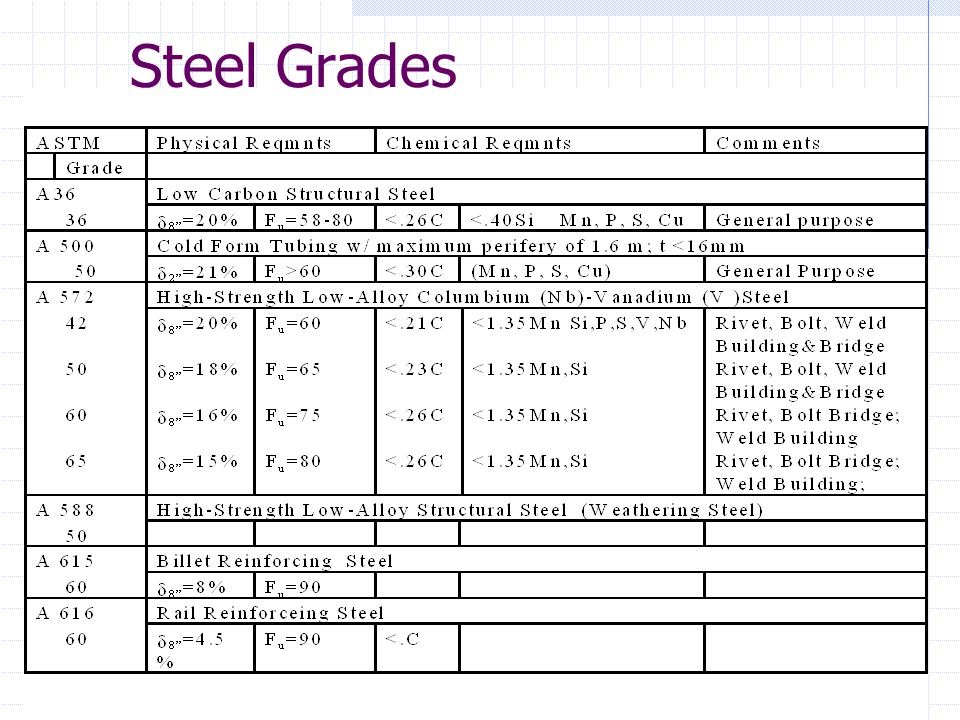

Steel Grades

All steel gets graded. The grade indicates alloy composition and other physical properties.

Many organizations have designated their own grading system for steel. Some of these organized grading systems include:

- SAE steel grades

- International Organization for Standardization

- European standards

- Japanese Industrial Standards (JIS)

- DIN standard

In the United States, steel is graded according to the SAE system.

Grading for Carbon, Tool, and Alloy Steel

Carbon, tool and alloy steel is assigned a four-digit number. The first digit in the number indicates the primary alloying element. The following list shows the designation assigned to each:

Carbon, tool and alloy steel is assigned a four-digit number. The first digit in the number indicates the primary alloying element. The following list shows the designation assigned to each:

- 1xxx: Carbon Steel

- 2xxx: Nickel Steel

- 3xxx: Nickel-Chromium Steel

- 4xxx: Molybdenum Steel

- 5xxx: Chromium Steel

- 6xxx: Chromium-Vanadium Steel

- 7xxx: Tungsten Steel

- 8xxx: Nickel-Chromium-Molybdenum Steel

- 9xxx: Silicon-Manganese Steel

The second digit indicates secondary alloying elements and their concentrations. This list is not exhaustive, but here are a few examples:

- 10xx: Plain Carbon Steel

- 13xx: Manganese Steel (Mn 1.75%)

- 32xx: Nickel-Chromium Steel (Ni 1.25%, Cr 1.07%)

- 34xx: Nickel-Chromium Steel (Ni 3%, Cr 0.77%)

- 72xx: Tungsten-Chromium Steel (W 1.75%, Cr 0.75%)

The second and third digits indicate the carbon percentage, in hundredths, by weight. For example, if the carbon content of steel was 0.30 wt %, the final two digits would be 30.

This means that SAE 1006 would be assigned to low carbon steel.

Grading for Stainless Steel

Stainless steel has a three-digit number system. Like with other steels, the first digit provides the primary alloying element. Here are the main categories:

- 1xx: Austenitic General Purpose Alloys

- 2xx: Austenitic Chromium-Nickel-Manganese Alloys

- 3xx: Austenitic Chromium-Nickel Alloys

- 4xx: Ferritic and Martensitic Chromium Alloys

- 5xx: Heat-Resisting Chromium Alloys

The following two digits further break down the categories.

Cold Hard Facts

With this guide to steel types and grades, you’re ready to tackle the world of steel construction. You know what it means to be medium carbon steel vs stainless steel. You know the difference between ferritic and tool steel.

Let Steel Buildings Zone take care of all your steel building needs.

Sources:

https://science.howstuffworks.com/engineering/structural/steel-best-material-for-building.htm

https://www.britannica.com/technology/alloy

https://www.thebalance.com/metal-profile-ferritic-stainless-steel-2340133

Leave a Reply